Capacitors for renewable energy applications

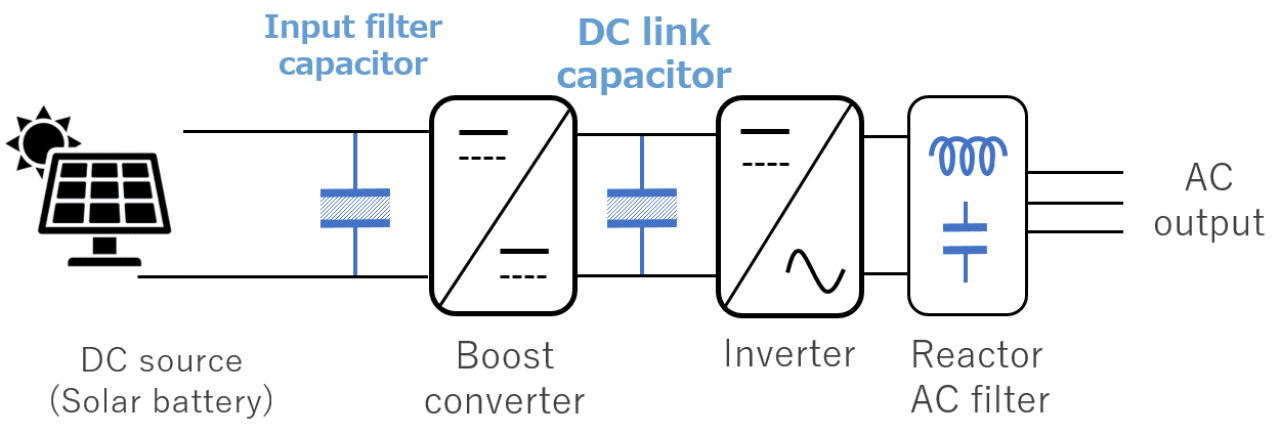

Renewable energy systems use high-power conversion technologies. Inverters are the core of these systems and incorporate high-voltage and high-capacitance units.

The efficiency of power conversion and reliability of long-term operation still the key points. Therefore, highly reliable DC link capacitors are required.

Solar Inverters – from 3 kW residential inverter up to 500 kW large central inverter - work typically with output voltages about 600V, 800V, and 1,000V.

Wind Power Inverter

Traditionally, aluminum electrolytic capacitors were used as DC link capacitors connected in series, but because they require periodic maintenance and replacement and have limited tolerance to overvoltage, large capacitance film capacitors are more and more used in recent large wind power inverters.

The outstanding withstanding voltage of the AIC film capacitors makes a significant difference here, when the no-load induced voltage of PMSG (permanent magnet synchronous generator) type generator increases in proportion to the wind turbine speed and DC-Link overvoltage must be absorbed.

Depending on the power range, maximum allowable voltage, available space, lifetime requirements, and design cost, either AIC aluminum electrolytic or AIC film capacitors have successfully proved their worth by meeting these requirements.

especially suitable series u.o.:

Capacitors for production automation and pumps

Motor drives – from small sized single phase domestical unit up to large 3 phase industrial application – offer the best performances when residual ripple voltage of the DC-Link is minimised.

Efficient energy buffers perform that for low-frequency ripple on the input side (100 Hz bis 300 Hz) and high-frequency component from the inverter (typically 8 kHz to 20 kHz). For that purpose, capacitor with the appropriate capacitance and ESR/ESL characteristics for each ripple current must be selected.

To compensate the self-heating effect in high power cases (lower capacitance, higher current capability) and extend the lifetime of the unit, forced cooling and heat sinks on power capacitors are effective measures.

For high-voltage motor drives with output voltages up to approx. 1.200V, we support you by selecting the best possible balancing resistors in combination with the series connection of low leakage current items to improve energy losses in devices that are permanently connected to the main power supply.

Our high ripple current series with optimized capacitance/current ratio are available with an improved internal structure to enhance heat dissipation for both PCB mounting (2-4 terminals Snap-In and tab mount type) as well as busbar screwing.

Our products suitable for motor drives

We provide 2, 3, and 4 terminal aluminum electrolytic capacitors with long life and high current ratings that can be mounted on printed circuit boards. We also offer lineup of capacitors with improved heat dissipation and heat sink friendly structures. For industrial motor drive applications, large screw terminal type aluminum electrolytic capacitors are available.

especially suitable series:

For servo drives with real time-controlled and instantaneous power distribution e.g. in response to the load torque or the speed curve, low losses at high energy density become a key parameter for effectiveness.

Aluminium electrolytic capacitors have been used successfully for a long time in the DC link of numerous servo drives with a very low failure rate. They act as high energy buffer as well as filter to remove high-frequency components.

Especially suitable snap-in and screw terminal type series for servo drives:

Capacitors for lifts, escalators and IT servers

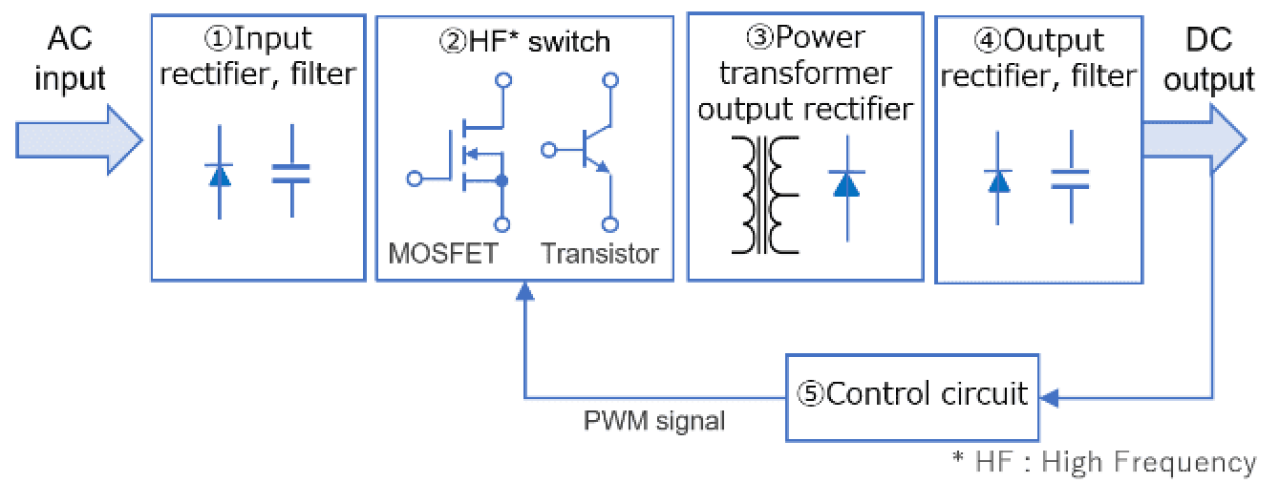

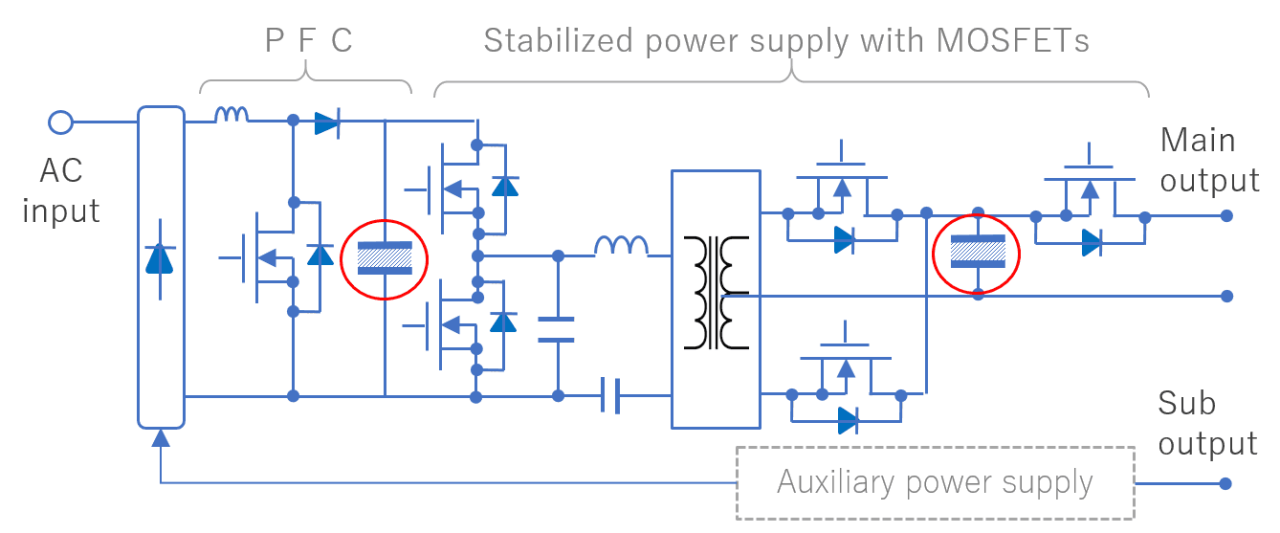

Recent switching mode power supplies (SMPS) are designed to be a most compact, lightweight, and cost optimized power supply with low power consumption and high-power conversion efficiency for electronic loads like rack mounted IT-server.

In response to the high switching frequency of the MOSFET or power transistors, some capacitor series have been further developed in the last decade to achieve the most possible compact design and increased current carrying capacity at higher frequencies.

Typical series of compact, long-life aluminum electrolytic capacitors with an optimized cost/performances ratio for use as energy buffers at the output of PFC and regulated power supply circuits are:

During normal operation of Uninterruptible Power Supplies (UPS), the battery and capacitors are charged and the capacitor ensures that no ripple current flows into the battery and that voltage peaks are absorbed. Both are decisive for the lifetime of the cost intensive batteries.

In the event of a brief power failure or voltage drop, the battery discharges to supply energy. However, as the battery does not react at lightning speed, a sufficient and quickly available energy reserve is required in the capacitor bank.

Summarized, capacitors for UPS application are required not only to have a large ability to store more energy, but also to be withstanding against peak voltage.

Therefore, aluminum capacitors (both snap-in and screw terminal types) with high withstand to surge voltage, large capacitance, and long life (less capacitance drop over lifetime) are predestined for UPS.

The following series meets these requirements:

Capacitors for electrical vehicles

In response to the growing electric car market or E-mobility market in general, the charging infrastructure and embedded power electronics are being continuously developed: Efficiency, higher performances, longer lifetime, and ranges at lower costs are the key challenges that the car manufacturers must face. Sustainability aspects also play a role in consumer decisions.

On top, time pressure in the R&D activities do not leave any room for long-lasting experiments and even worse, for wrong decisions.

That´s why AIC support your team hand in hand with the product manufacturer during the qualification procedures with feasibility studies, PPAP and all processes in frame of the IATF 16949 and VDA 6.3 requirements.

The following overview shows high-end AEC-Q200 compliant aluminum electrolytic and metallized film capacitors for stationary and on-board charging systems in addition to 100% mechanical and electrical customized film cap modules for compact powertrain units. These capacitors offer optimized heat dissipation and have successfully proved their worth in automotive applications.

Capacitors for rolling stock

Under Traction control systems, we consider units that control the driving force of trains and other grid supplied E-Vehicles as well as braking operations, with or without auxiliary lighting and power supply tasks for rolling stock.

The regulation of speed and torque as well as the backflow of regenerative braking energy to the source pose the greatest challenges by lowering switching losses, withstanding peak voltage, and enhancing thermal management. Therefore, more and more low ESR film capacitors are used for speed control of the large electric motors in railcars, contributing to significant extension of the maintenance intervals.

Auxiliary power supplies for electric railcars require capacitors as energy buffers and as a filter to prevent high-frequency components of the inverter from interfering with the main power input. Aluminum electrolytic capacitors or film capacitors – both with high ripple current capabilities are used.

AIC manufacture not only high withstand voltage and low loss film capacitors, but also large screw terminal type aluminum electrolytic capacitors with high ripple current ability and optimized heat dissipation for optimal cooling.

Capacitors for pulsed energy applications

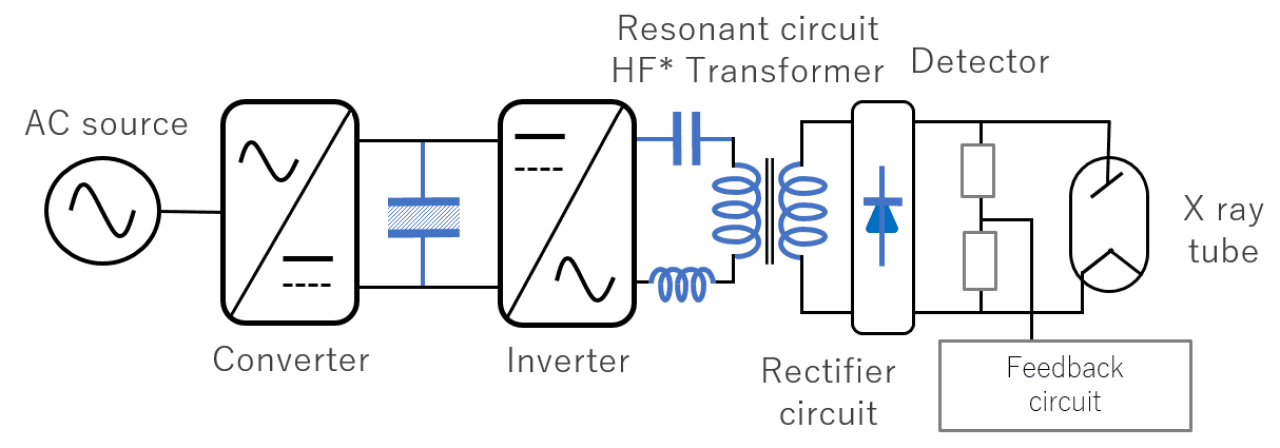

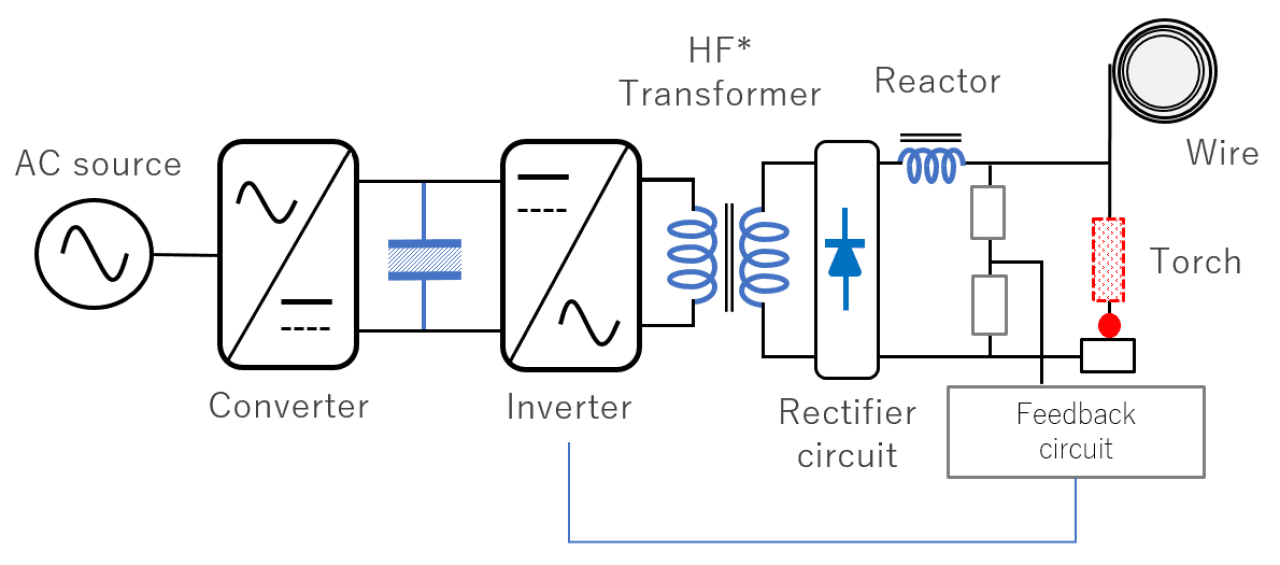

The capacitor bank in Pulsed Power Supply using in X-ray generators, welding machines, medical lasers, high-frequency plasma torches, particle accelerators etc is faced to continuous and deep charge-discharge operations at a wide possible cycle frequency range.

Depending on the needed energy and consequently the discharge level of the bank, both aluminum electrolytic and film capacitor technology are suitable. For discharges in the range of 30% to 50% of maximum operating voltage, aluminum electrolytic capacitors offer more capacitance, thus larger energy boost.

In particular for aluminum electrolytic capacitors, special designs of anode and cathode foil are mandatory to enable a deeper discharge level and to assure a useful lifetime. In addition, the ESL is also decisive, since a large ESL may increase transient signal generation. For large screw terminal type capacitors, an low ESL value around 10nH is generally required.

To master these requirements, AIC offers dedicated 2-4 pins snap-in series as well as large capacitance screw terminal (W) Series with high capacitance, long life, and high heat dissipation design for deep charge-discharge applications. Furthermore, several other screw-type series can be ordered with optional charge-discharge properties.